Non-Toxic Calcium Zinc Stabilizer

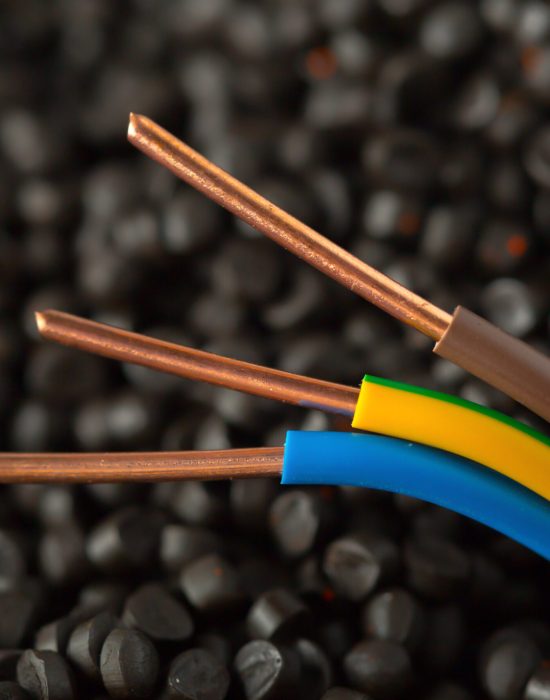

Calcium Zinc Mix Stabilizers represent a non-toxic alternative to traditional heavy metal stabilizers such as lead and cadmium in PVC formulations. These stabilizers consist of calcium and zinc salts of carboxylic acids, offering heat stabilization and lubrication properties without the environmental and health concerns associated with heavy metals.

Typically comprising a blend of calcium stearate, zinc stearate, and other carboxylates, calcium zinc mix stabilizers are formulated to provide thermal stability, processability, and UV resistance in PVC applications. They are compatible with various processing techniques and maintain the mechanical and physical properties of PVC products.

Calcium zinc mix stabilizers are widely used in the production of PVC pipes, profiles, sheets, and fittings where heat stabilization is essential. They ensure the durability and longevity of PVC materials while complying with regulatory requirements for non-toxicity and environmental safety.

These stabilizers are integral to the construction industry, where PVC-based products are used extensively in building materials such as window profiles, siding, and roofing membranes. Their ability to withstand weathering and environmental exposure makes them ideal for outdoor applications.

In medical-grade PVC formulations, calcium zinc mix stabilizers are preferred due to their non-toxic nature and compatibility with healthcare standards. They ensure the safety and reliability of PVC medical devices, including tubing, IV bags, and surgical instruments.

Calcium zinc mix stabilizers are considered safe alternatives to heavy metal stabilizers in PVC applications, offering comparable performance without the associated health risks.

They comply with regulatory standards for consumer products and industrial applications, ensuring product safety and environmental responsibility.

Unlike lead and cadmium stabilizers, calcium zinc mix stabilizers pose minimal environmental risks due to their non-toxic composition and compatibility with recycling processes.

They support sustainable practices in PVC manufacturing by reducing hazardous waste and promoting the circular economy.

TECHNICAL DATA

| Grade Name | Appearance | % Volatiles,105°C 2hr Max | Ash Content % | Bulk Density g/l | Mesh Size 97% Pass through | Application |

| RK CZ 555 | White Powder | 3.0 | 54 ± 3 | 400-500 | 200 Mesh | PVC Profile,PVC Rigid, PVC Flexible Pipe, Cables |

| Grade Name | Appearance | % Volatiles,105°C 2hr Max | Thermal Heat Stability | Bulk Density g/l | Mesh Size 97% Pass through | Processing with PVC up to | Application |

| RK CZ 240 | White Powder | 3.0 | 130°C | 400-500 | 200 Mesh | 180°C | PVC Wires & Cable Compounding |

We can manufacture as per customer specifications and requirements

All grades are vegetable based and Non Toxic.

Features